Meilunbio® has set up an independent quality control department, and at the same time, it has cooperated with a number of authoritative third-party testing organizations for a long period of time, and has conducted stringent tests on the relevant products in accordance with the Pharmacopoeia, the ICH, or the relevant regulations of foreign countries.

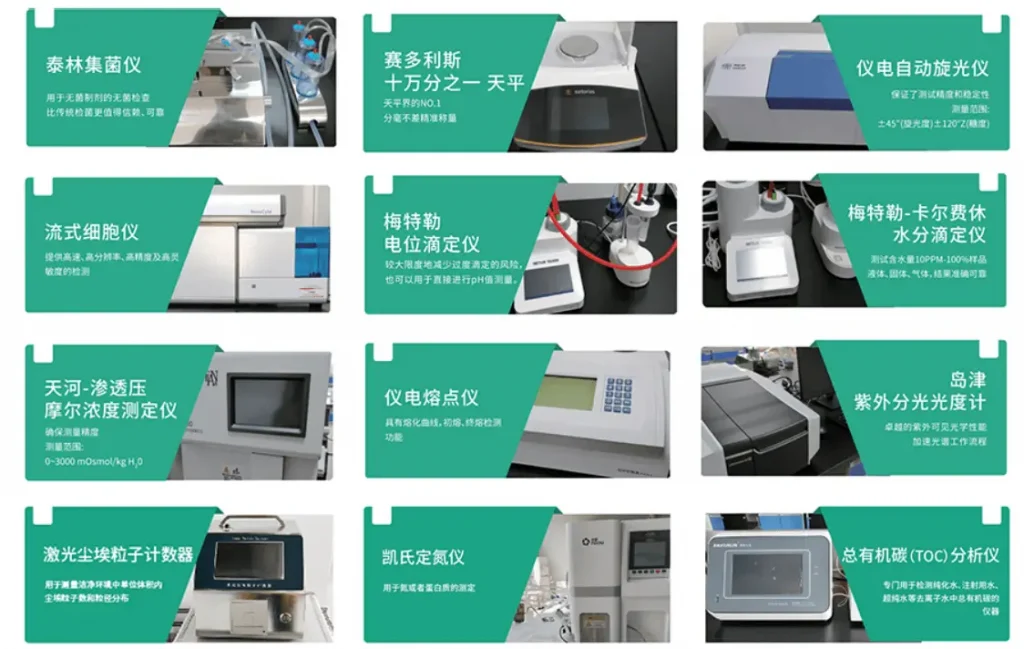

We have an independent and perfect quality control center. The center is equipped with advanced testing instruments and purchases standard products from the U.S. Pharmacopoeia, European Pharmacopoeia, CIQ and other authoritative organizations.

In addition, in view of the special characteristics of many biological reagents, we will test the effect of their use through immunology, cell biology, pharmacology and other technical methods.

Pharmacopoeia listed products

From raw materials, intermediate processes to end products, MeilunBio® conducts detailed testing in accordance with the Pharmacopoeia and ICH regulations.

Non-pharmacopoeia-listed products

MeilunBio® establishes analytical methods, carries out method validation and rigorous testing.

Biological reagent products

Meilunbio® strictly compares with international mainstream brand products, and carries out all-round validation for different samples with different application.

Product Packaging

MeilunBio® takes compatibility tests and conducts frequent sampling tests after subcontracting, so as to ensure that this packaging material is suitable for the packaging of the product.

Product storage

MeilunBio® has a product storage warehouse that complies with GMP standards. All products are placed in categories and have a complete in-bound/out-bound system. For products that require special storage, we promise to monitor the temperature and humidity of the storage environment at all times to ensure product quality.

All batches of products

MeilunBio® conducts retained sample tests for all batches of products with a validity period of up to 1 year. No matter what questions users have, we will solve them effectively as soon as possible.

Product Shipment

MeilunBio® will send an original copy of our test report with the goods, including batch number, date, test indicators, etc.

If you have any questions in use, please feel free to contact our company, we will be the first time to answer your questions.

Introduction to Mylan Bio’s Quality Control Process

Departmental Organization

QC, QA independent department

QC 1 Physical and Chemical Testing Department: Responsible for the physical and chemical properties of the products (including but not limited to), such as appearance, solution clarity, pH, odor, melting point, optical rotation, moisture, ignited residue, titration of inorganic salts and the establishment of the corresponding analytical methods.

QC 2 Organic Detection Department: Responsible for H-NMR analysis, MS mass spectrometry, infrared (IR)/UV (UV) spectroscopy, HPLC/GC content determination of organic substances, and the establishment of corresponding analytical methods. Equipped with one PhD, two masters, and one appointed technical consultant (dDoctoral advisor).

QC 3 WB product quality control department; responsible for the quality control of all WB products, including protein cleavage, electrophoresis, chemiluminescence, gel imaging, gel preparation effect, etc., and the establishment of corresponding analytical methods. Equipped with two master’s degree holders.

QC 4 Cell Biology Quality Control Department: Responsible for the quality control of all cell culture and assay products, including sterility test, culture effect test, proliferation effect test, apoptosis effect test, staining effect test, bioactivity test and so on. Equipped with 2 master’s degree holders

QC 5 Raw materials and packaging materials control department: responsible for packaging materials, sealing, high temperature and low temperature stability, sterility, and various types of raw materials testing, involving the above four parts of the project, forwarded to other departments for testing. QA manager is responsible for all QC test results and reliability of analytical methods, reporting to the general manager. Unqualified products will be destroyed directly without reporting. At the same time, corresponding production manager is ordered to self-examination to eliminate quality hazards. Because the production process and verification methods of all products have been determined internally by the company before they are launched on the market, in principle, the methods will no longer be updated, but self-examination will be the main focus. If the production process needs to be updated, it needs to be reported to the general manager for discussion and decision.